Nanocellular Foam

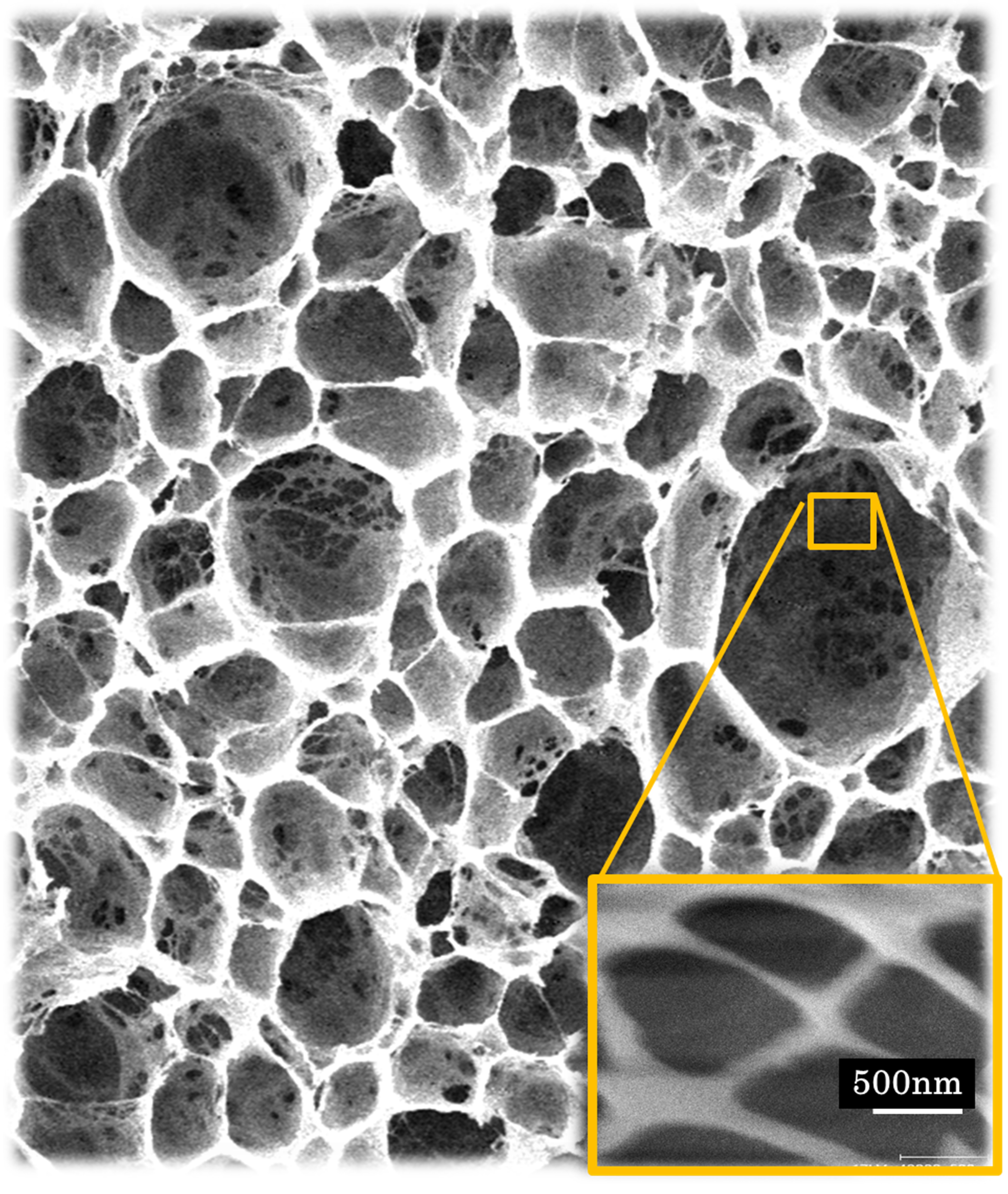

In recent years, nanoscale, porous, structured polymer materials have attracted significant attention. We have been working on develop-ment of nanocellular foams (NCFs) of thermoplastic resins foamed by CO2 or N2 gas. Fig. 1 shows a polypropylene foam fabricated by N2 foaming with a crystal nucleating agent using core-back injection molding. Nanofibril structures are formed on the cell walls (Inset). The split of crystal lamellae induced by the bubble formation at the crystal phase resulted in the formation of such nanofibrils.

Environmentally-benign Electroless Plating

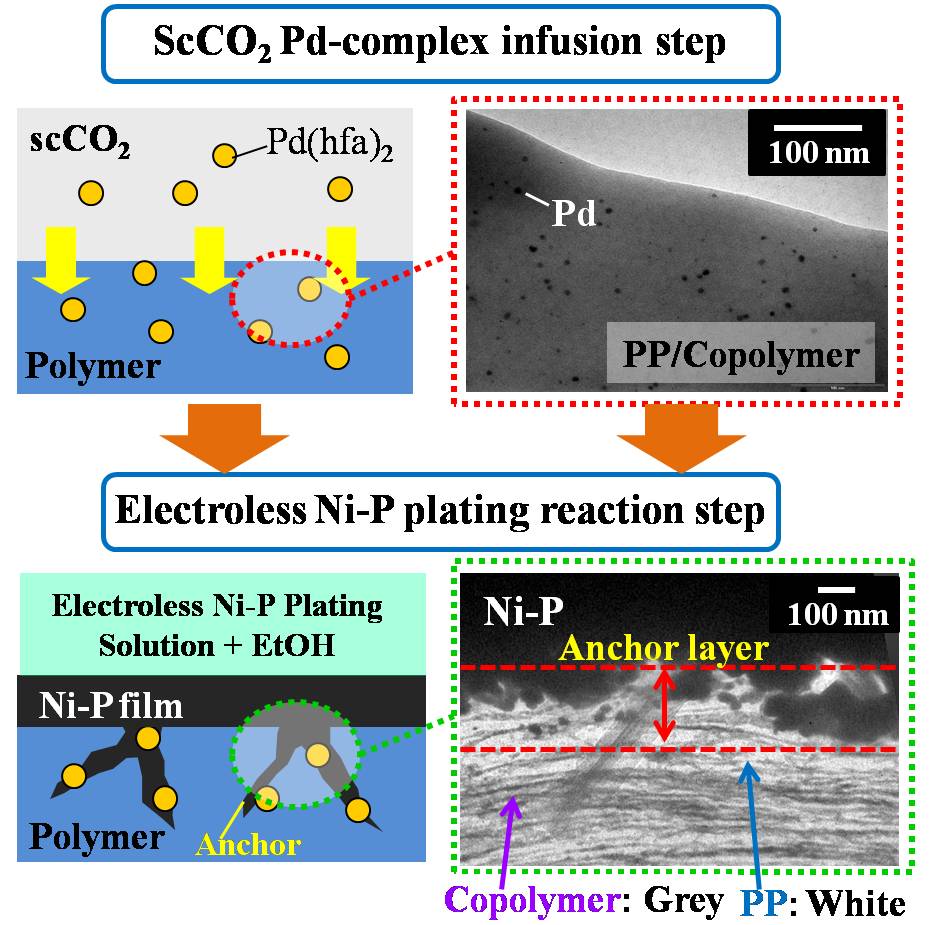

The conventional electroless plating on plastic resins requires the use of strong acid and a large amount of water to impregnate the plastic with catalyst. We have been developing a new environmentally-benign electroless plating process using supercritical CO2 that dissolves the precursor of catalyst and plasticizes the resin. Recently we succeeded in the electroless plating on strongly hydrophobic polypropylene by blending it with a hydrophilic copolymer (Fig. 2).

Nanofibers by Electrospinning

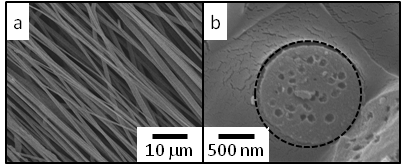

Electrospinning is a simple method for producing polymer nanofibers by applying a high voltage to the polymer solution. We have been studying on the fabrication of nanofibers with core-shell or porous structure. Fig. 3 shows SEM image of porous carbon nanofibers prepared from PVA. The unique pore structure was formed derived from salt particles generated by the decomposition of surfactant during carbonization process. The application of the porous nanofibers as electrodes of electric double layer capacitor is being studied.

Simulation of Directed Self-Assembly of Block Copolymer

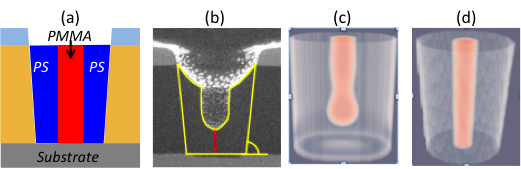

The directed self-assembly (DSA) has recently gained a large attention from semiconductor industry as an viable option for sub-10 nm patterning. The DSA utilizes a phase separation of block copolymer (e.g. PS-PMMA) to generate periodic patterns on a chemically/physically pre-patterned surface. In this study, we provide some insights into the origin of the DSA defects by performing computer simulations. A simplified model, so-called the Ohta-Kawasaki (OK) model, is employed here. Compared with the other well-established DSA simulation methods, e.g., SCFT and MC, the OK model is computationally very inexpensive, whereas it may provide reasonably accurate results. Fig. 4 shows an example of our simulations results. It is observed that the morphological defect (i.e. PS residual layer between the tip of PMMA cylindrical domain and the substrate) in Fig. 4c can be removed by replacing the PMMA-attractive bottom surface to the neutral one (Fig. 4d). We are currently working on the development of new simplified DSA model which is applicable to more complicated shape of the guide patterns and design of the block copolymers.

Nondestructive Measurement of Polymer Property

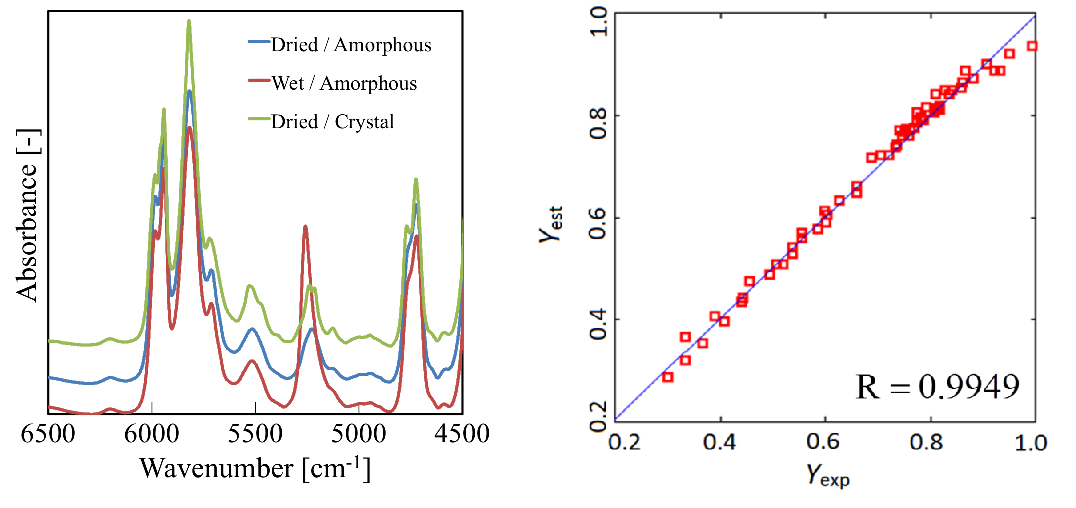

We developed a new application of near-infrared (NIR) spectroscopy for the quality control of polylactide (PLA). Fig. 5 (a) shows NIR spectra of PLA film with different water content and crystallinity. For the estimation of water content in PLA, the partial least squares (PLS) regression models were derived from NIR spectra (Fig. 5(b)).